39 ppap process flow diagram

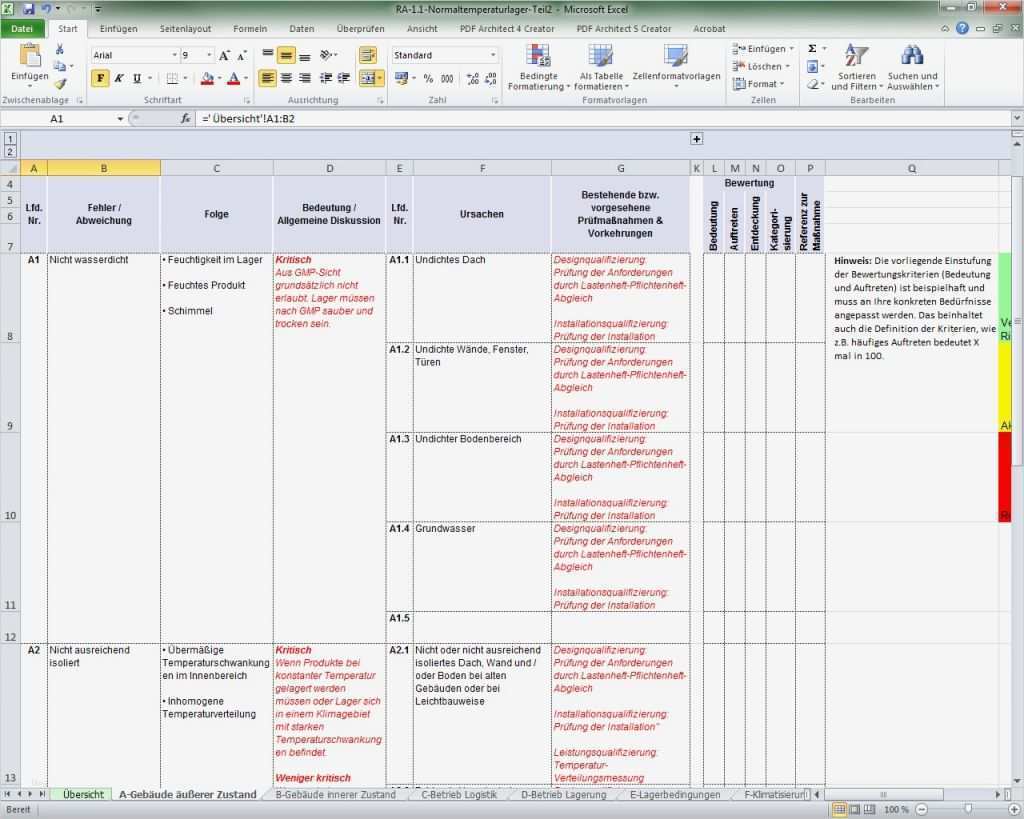

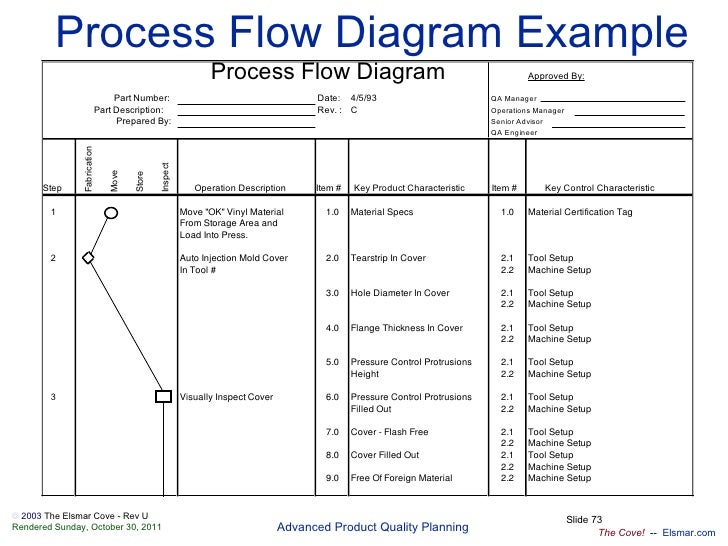

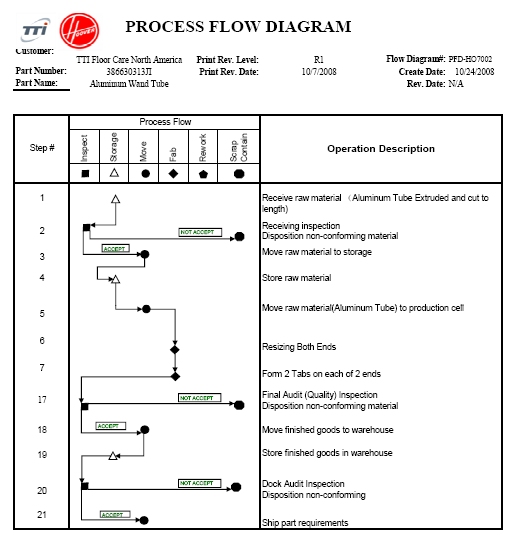

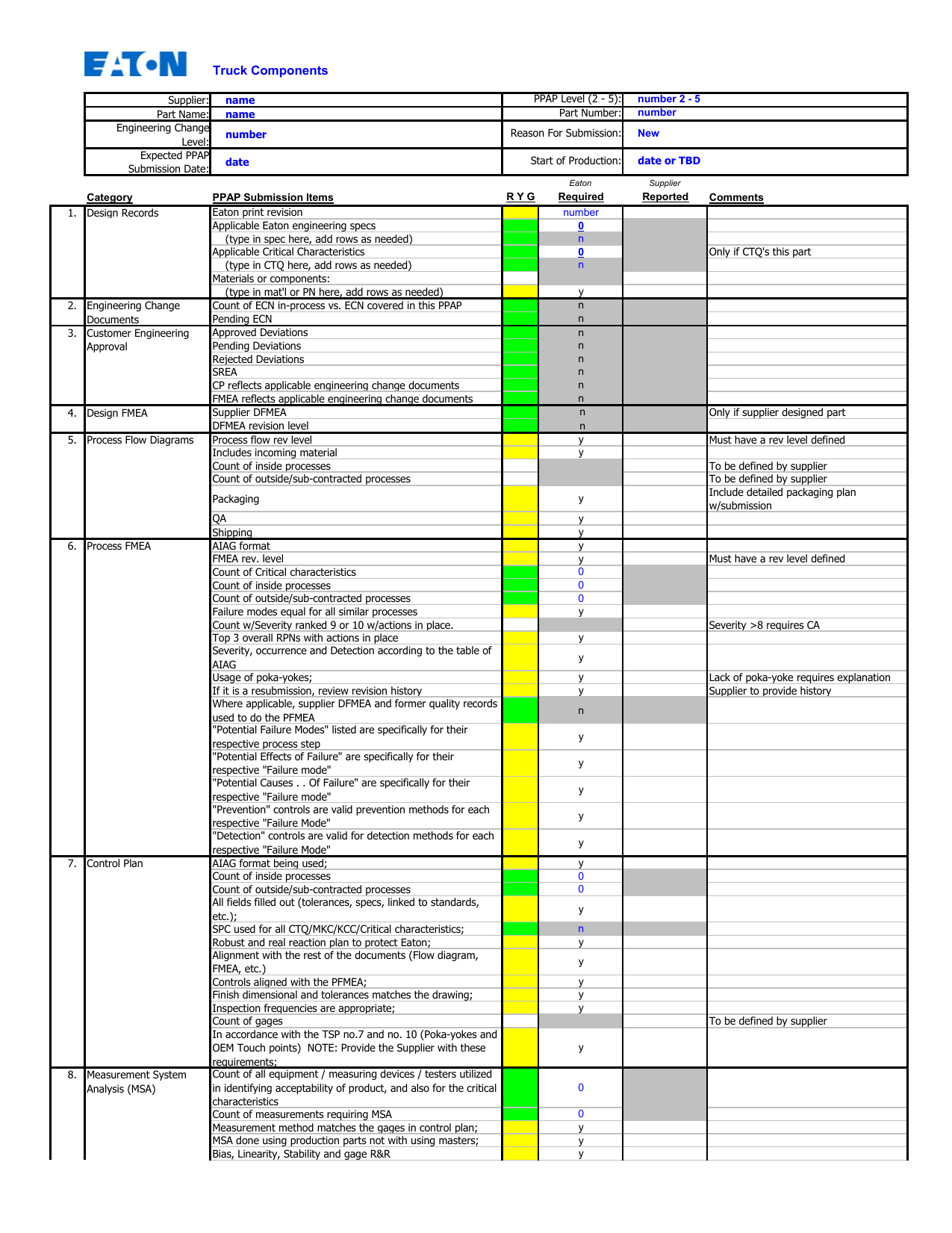

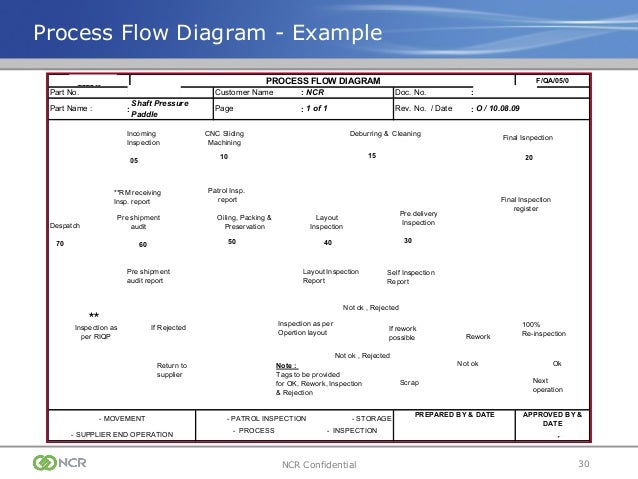

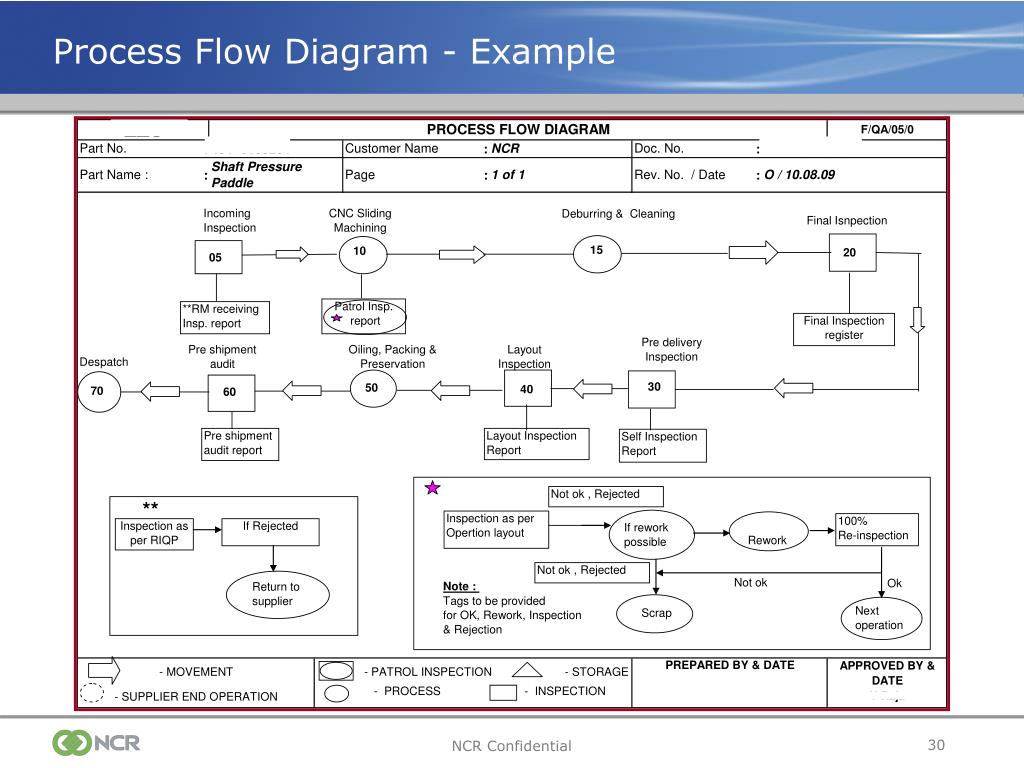

7.4 NCR PPAP Process 13 8 Explanation on PPAP requirements 13 8.1 Requirement 1: Design Records 13 8.2 Requirement 1a: Balloon drawing 13 8.3 Requirement 2: Approved Engineering change document 14 8.4 Requirement 3: Customer Engineering Approval 14 8.5 Requirement 4: Design FMEA 14 8.6 Requirement 5: Process Flow Diagram 14 PPAP Element #5: Process Flow Diagram(s) • Step by Step designation of the process flow required to produce the referenced product which meets all customer requirements - Provide linkage to PFMEA and Control Plan - Traditional block diagram - May employ "Family" based diagrams - Should cover all steps from Receiving to Shipping

and Production Part Approval Process (PPAP) Guidance Material. Company Confidential. This document does not contain any export regulated technical data. AS9145 standardizes the requirements for the Product Development Process (PDP) ... • Process flow diagram* • Floor plan layout

Ppap process flow diagram

Production Part Approval Process (PPAP) ... Process Flow diagram is required to outline and standardize the production process that is being approved. This should outline the entire process that is being used to manufacture the. component & assembly. PFMEA. Please use one of the standard AIAG Process Flow Diagram Forms. In some cases Westport will allow Family Group Process Flow Diagrams (PFD's), FMEA's and Control Plan. When this is agreed upon, the supplier shall have a reference attachment for all part numbers and individual part differences of the parts in the Family Grouping. 6. Feb 9, 2018 — To describe one of elements of Nilfisk Production Part Approval Process (PPAP) - Process Flow. Diagram (PFD):.5 pages

Ppap process flow diagram. PPAP Assessment www.quality-one.com Page 4 of 15 with the Design Record, FMEAs, Control Plan, Work Instructions and ALL APQP documentation. Process flow diagrams for "families" of similar parts are acceptable if Production Part Approval Process (PPAP) Flow Chart. Identify PPAP. Requirements at. APQP/Customer. Purchase Order. Fail Safe. Update IML Tools SO.1 page Process Flow Diagram, also known as a process flow chart, shows the document and clarifies all steps required in the manufacturing of the part in question. Production Part Approval Process (PPAP) is the industry standard that ensures engineering design and product specification requirements are met. Through the PPAP guideline, suppliers and customers understand the requirements to obtain part approval of supplier manufactured parts. Applicable to all parts and commodities, application of these ...

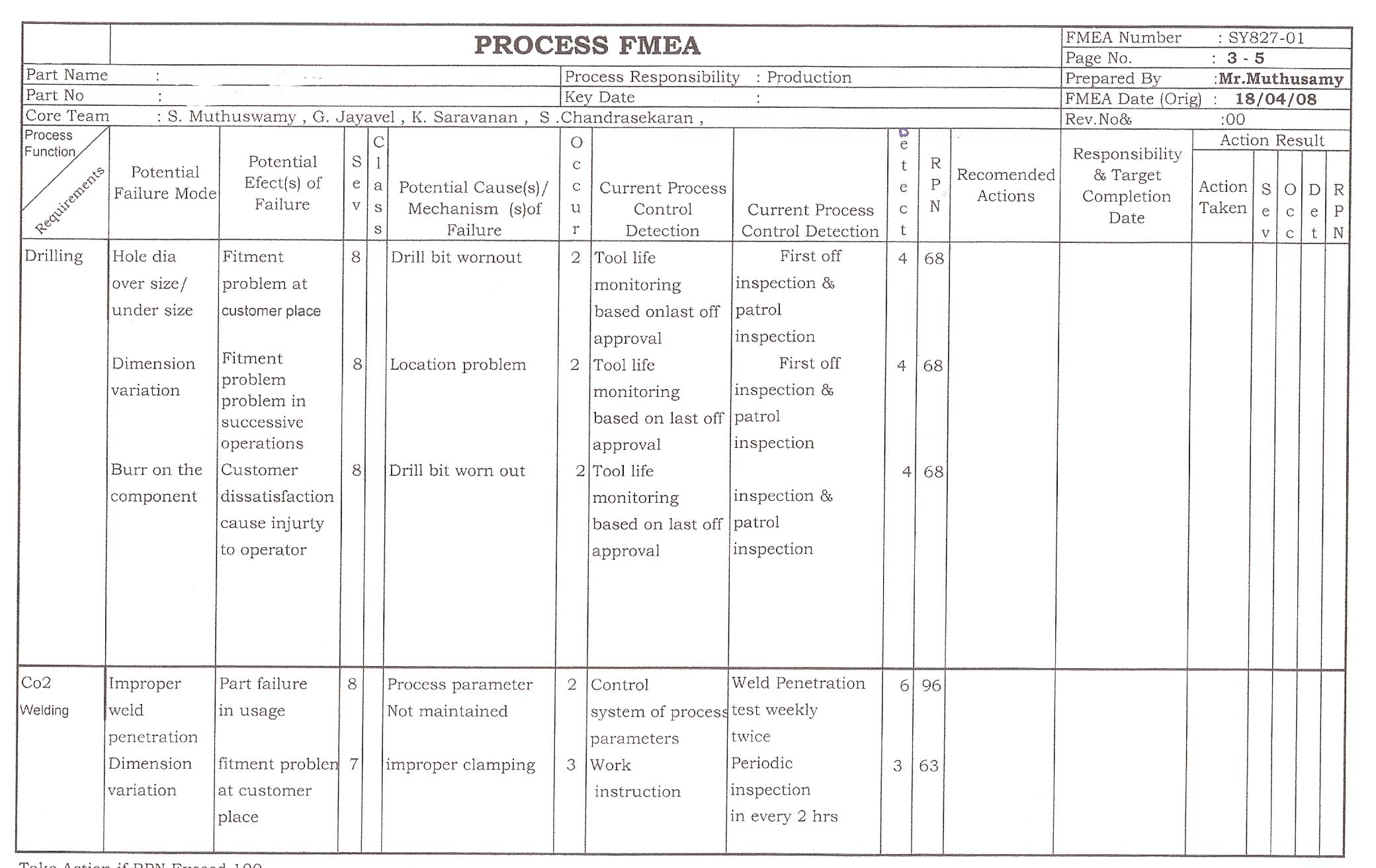

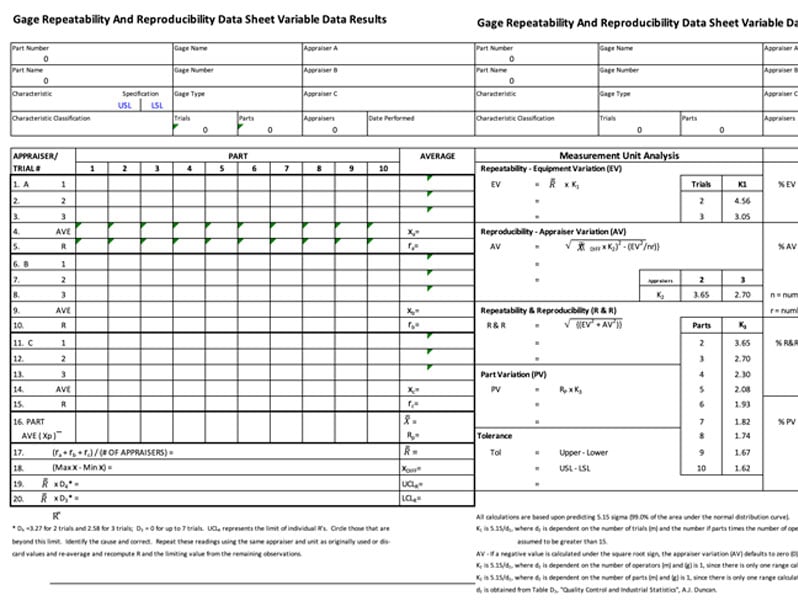

Process Flow Diagram & Process FMEA Control Plan Measurement Systems Analysis Process Capability & Control PPAP Webinar Objectives • Provide high level understanding • Introduce APQP and PPAP and show relation to 9145 • Share benefits & best practices • Provide sources of additional information PPAP Requirements: 5.Proces Flow Diagram (PFD) 14 Process Flow Diagram is a way to visualize a process and must meet specified customer needs. After review, it should be clear what the process includes: 1. Each step in the process (receiving of raw material, part manufacturing, inspections and checks, assembly, packaging, shipping) 2. 3.3 PROCESS FLOW CHART. The process flow chart is a schematic representation of the current or proposed process flow. It can be used to analyze sources of variations of machines, materials, methods, and manpower from the beginning to end of a manufacturing or assembly process. It is used to emphasize the impact of sources of variation on the ... Process Flow Diagram PFMEA Control Plan Product-Process Change 4th Design Matrix 4th Bulk Materials Reqts 4th Performance Test Results 4th ... Complete this form and email to your customer organization whenever customer notification is required by the PPAP Manual in Table 3.1. Your customer will respond back with an acknowledgement and may ...

PPAP Element #5: Process Flow Diagram(s) Step by Step designation of the process flow required to produce the referenced product which meets all customer requirements. Provide linkage to PFMEA and Control Plan. Traditional block diagram . May employ "Family" based diagrams. Oct 1, 2021 — PPAP PROCESS FLOW CHART . ... Process Flow Diagrams must: . ... The Supplier must have a process flow diagram in a format that clearly ...29 pages PFD (Process Flow Diagram) Lab Test Report; DFMEA (Design Failure Mode and Effects Analysis) PFMEA (Process Failure Mode and Effects Analysis) MSA Study (measurement system analysis) SPC (Statistical Process Control) PPAP approval. PPAP is a series of documents gathered in one specific location (a binder or electronically) called the "PPAP ... Element 3 Process Flow Diagram The purpose of the Process Flow Diagram is to document the steps required in the manufacturing of the part. The Main process steps must match both the Process Failure Mode & Effects Analysis, and the Control Plan. The Process Flow should include the entire process, from Receiving through Shipping.

Full name is Production Part Approval Process. Oct 7, 2019 - PPAP is a very important tool for establishing confidence in product supplier & their production processe. ... The examples of business process diagrams - flow charts are drawn using the ConceptDraw DIAGRAM. - Marci. A - Business Flow Charts. Project Management Certification. Program ...

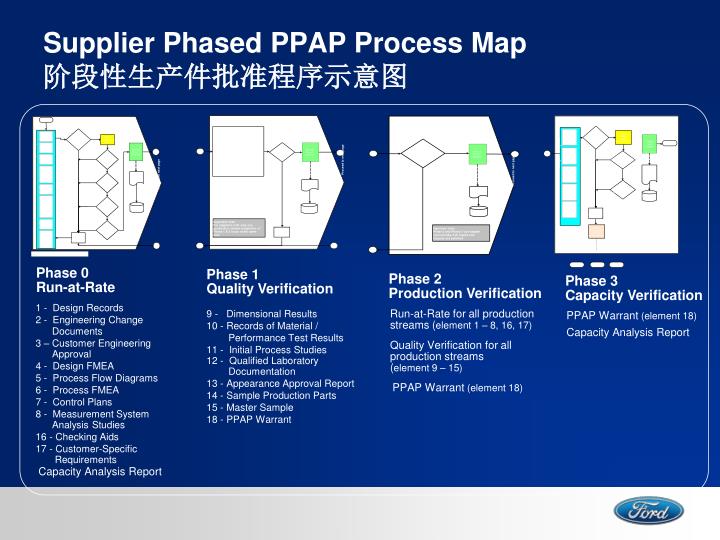

→ PPAP is the Production Part Approval Process. → It is a very important tool for establishing confidence in product suppliers and their production processes." → ISO 9001:2015 and IATF 16949:2016 is used to formally reduce risks prior to product or service release, in a team-oriented manner, using well-established tools and techniques.

Nov 5, 2019 — C. Process flow diagram. Yes. No. No. D. Control plan. Yes. No. No. E. Material test results. Yes. Yes. No. F. Performance test results.

#ppap #sigmayouthengineers #cnc #process process flow diaggram

5. Process Flow Diagram Y E S N O Is the Process Flow Diagram legible and in a format that can be understood by the Customer? Are product references aligned to the customer submission? I.e.: Part number, latest drawing issue, facility references etc. Was the manufacturing process flow chart developed by a cross functional team?

PPAP Process Requirements 5 -Process Flow chart A control plan of the process should be included in your PPAP submission. It should mirror the PFEMA and be signed by the relevant parties. You may want to include areas such as early production containment. This area can also be seen as a Pre-Launch Control Plan if

This document defines Production Part Approval Process (PPAP) requirements as agreed upon by the following business entities herein referred to as "Member". ... 5.3 Element 3 - Process Flow Diagram (PFD) 9 5.4 Element 4 - Process Failure Mode and Effects Analysis (PFMEA) 10

This procedure defines PPAP related terms and all aspects of the PPAP process, including when a PPAP submission is required, what the general PPAP submittal requirements are and what the possible outcomes and consequences of a PPAP submission are. In addition to the description provided in the Manual's sections, PPAP process flow charts are ...

The Process Flow Diagram should match the control plan and the Process Failure Mode and Effects Analysis (PFMEA) and also includes the flow of non-conforming materials and parts. 6. Process Failure Mode and Effects Analysis (PFMEA)

- Process Flow for Lean management - Characteristics matrix - M E O S T for product validation - Quality plan - Gantt chart - Quality planning sign-off • Phase 4 of APQP : Linkage to PPAP • Successful PPAP through structured APQP Process •Five Phases of APQP -with exercises •Control plan - Creation & management

Production Part Approval Process (PPAP) Software. Create and manage Internal and Supplier PPAPs. Generate Control Plans, PFMEAs, and Process Flow Diagrams in minutes. Collect and manage Initial Sample Reports, Process Capability Studies, Material Certs, PSWs and more. SIMPLIFY PPAP CREATION.

Title: PPAP Forms from SQR Author: Kohler Company Last modified by: ko43386 Created Date: 6/11/1999 3:57:51 PM Other titles: Intro PPAP Checklist Packaging Checklist Warrant Dim Results PPAP Performance PROCESS FLOW DIAGRAM DESIGN FMEA Process FMEA CONTROL PLAN APPEARANCE Revisions 'Dim Results'!Print_Area Warrant!Print_Area 'PROCESS FLOW DIAGRAM'!Print_Titles

The Process Flow Diagram outlines the entire process for assembling the component or final assembly in a graphical manner. The process flow includes incoming material, assembly, test, rework and shipping. Process Failure Mode and Effects Analysis

In the AIAG 4th edition of the PPAP book page ii shows a PPAP Process Flow Diagram in a pictorial format - and please remember the AIAG is a suggested set of guidlines to follow and in some cases are fully accepted by our customers and in other cases they are less interested in having a specific format.

The purpose of the Production Part Approval Process (PPAP) is: ... Process Flow Diagram 7. PFMEA 8. Control Plan 9. Measurement Systems Analysis (MSA) 10. Dimensional Results 11. Material, Performance Test Results 12. Initial Process Study (Cpk) Capability Studies

The Process Flow Diagram should match the control plan and the Process Failure Mode and Effects Analysis (PFMEA) and also includes the flow of non-conforming materials and parts. Overview table of the PPAP Process Requirements: German and English. Requirements 1 to 18 and respective the Submission Levels 1 to 5. Legend: S | R | *

Feb 9, 2018 — To describe one of elements of Nilfisk Production Part Approval Process (PPAP) - Process Flow. Diagram (PFD):.5 pages

Please use one of the standard AIAG Process Flow Diagram Forms. In some cases Westport will allow Family Group Process Flow Diagrams (PFD's), FMEA's and Control Plan. When this is agreed upon, the supplier shall have a reference attachment for all part numbers and individual part differences of the parts in the Family Grouping. 6.

Production Part Approval Process (PPAP) ... Process Flow diagram is required to outline and standardize the production process that is being approved. This should outline the entire process that is being used to manufacture the. component & assembly. PFMEA.

0 Response to "39 ppap process flow diagram"

Post a Comment