41 air compressor dryer installation diagram

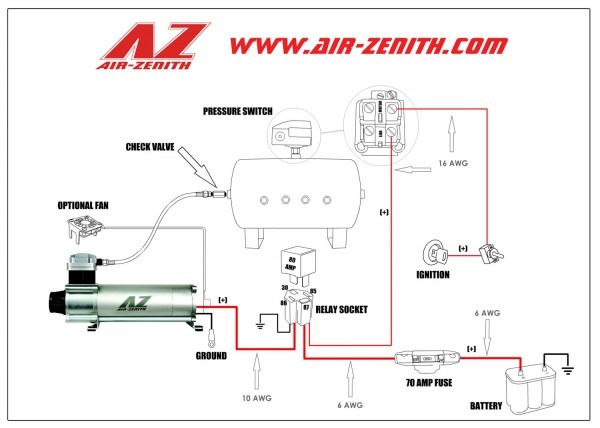

How to install air compressor lines and air dryer for air compressor. You can buy the Air Dryer here: http://www.usaweld.com/Max-Dry-for-Plasma-Cutters-p/253... Air Compressor Wiring Diagram – air compressor capacitor wiring diagram, air compressor starter wiring diagram, air compressor wiring diagram, Every electrical structure consists of various different parts. Each component should be placed and connected with other parts in specific way. If not, the arrangement won’t function as it should be.

recommended procedures, as you may need to replace the wiring harness to the air dryer heater. 3. Verify there is a constant downward angle of the inlet line from air compressor to air dryer. If there are kinks or sags, reroute. Total inlet line length from compressor to dryer should be a minimum of 7 feet and a maximum of 19 feet.

Air compressor dryer installation diagram

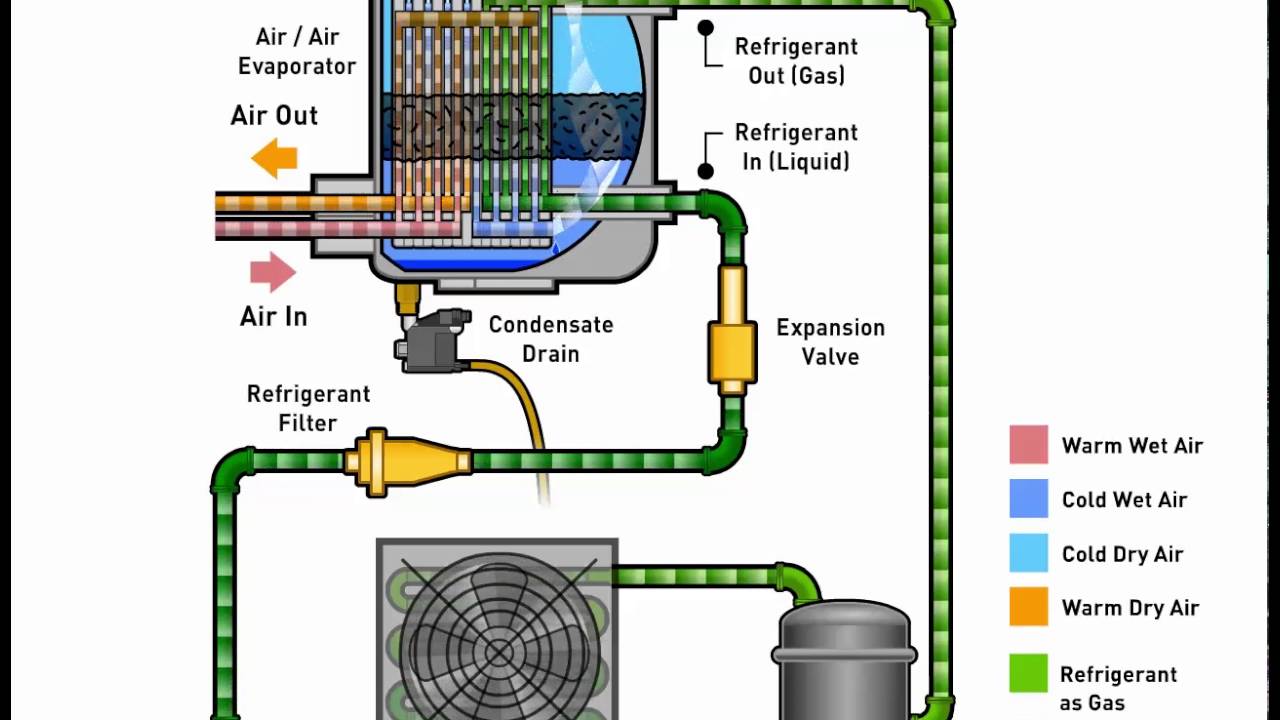

high-performance dryers remove the moisture from your compressed air with a standard pressure dew point of -20°C/-5°F, -40°C/-40°F and -70°C/-100°F. For complete peace of mind, you can even set your dew point to meet the specific needs of your application. Enjoy easy installation and long maintenance intervals Big sandy recc paintsville ky 606 789 4095. This is simple to read and easy to use. Eimed60jmb dryer pdf manual download. I have a new sanborn 80 gal 240volt single phase 52 hp air compressor. Make sure you use this to check voltages before connecting. View and download electrolux eimed60jmb wiring diagram online. Remove wet air by installing a refrigerated or desiccant dryer from Compressor World. Compressed air dryers are used to eliminate water moisture from your air compressor lines. Whether you're looking for an industrial or medical grade compressed air dryer, we offer a wide selection of air dyer systems and parts. Shop today for the best prices and free shipping from the experts at Compressor World!

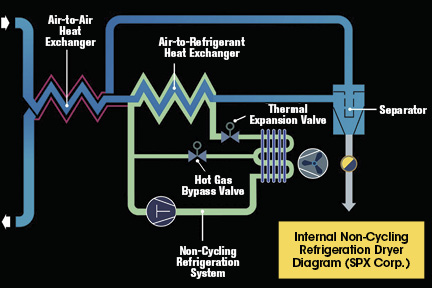

Air compressor dryer installation diagram. Wire A 220 Air Compressor To 110 Step By Guide. Figure 7 air compressor wiring diagram to 110v devilbiss pro installing the magnetic starter for 220 volt 2 wire 5hp single phase is a 5 hp pressure switch all 145 psi with relay 110 or and doityourself horn special duty 115 230 3450 rpm marathon motors electric tender an in boxcar step ratings diy home diagrams refrigeration storage tank sdaire ... Precaution: Identify the air compressor circuit, turn it OFF and Tag it with a Note before working with the 220 volt air compressor wiring. Circuit Wiring for a 240 Volt Air Compressor. Circuit Size for an Air Compressor The circuit size will depend on the size of the air compressor and the horsepower rating of the motor. 1 A) When operating the air dryer the operator must apply safe working methods and observe all local safety instructions and relevant regulations. B) Prior to installation, the dryer and the compressed air system are to be depressurized and disconnected from the electrical main supply. C) The user is responsible for safe operating conditions.Parts and accessories must be replaced if inspection 4.3 Wiring Diagram 5. Installation 13 5.1 Storage ... compressor house. The dryers have been designed for nominal standard inlet conditions as per ISO 7183 in order to obtain a dew point under pressure of +3oC to +7C. ... The Air Dryer is switched ON/OFF using Dryer ON/OFF switch. The moment Dryer is switched ON, built in Anti-Recycling

26.0 flow diagram 27.0 pressure switch adjustment 28.0 dryer calibration 29.0 voltage conversion - wiring diagram (on the back cover) important: a copy of the wiring diagrams can be found inside the electric board of the compressor. rotary screw compressor units hp 3 - 5 - 7.5 kw 2.2 - 3.7 - 5.5 machine and manufacturer identification data Remove air line from outlet side of the air dryer. 2. Install 1/2 inch Street Tee in outlet side of dryer. 3. Install air line in opposite end of the tee. 4. Install SURE-CHANGE in side port of the tee. One time purchase. no need to replace. after the desiccant is changed, Sure-Change turns back to blue. 1.312 HEX 1.25 26.0 flow diagram 27.0 dryer calibrations 28.0 voltage conversion - wiring diagram (on the back cover) important: a copy of the wiring diagrams can be found inside the electric board of the compressor. screw compressor units hp 10 - 15 kw 7,5 - 11 machine and manufacturer identification data position of the identification plate fig. 1 fig. 1 1 Air Compressor Installation Diagram.pdf. A collection of over 9,230+ 2D construction details and drawings for residential and commercial application. One Hundred Twenty major categories of fully editable and scalable drawings and details in AutoCad Format. These are a perfect starting point for modification to meet your particular needs or just ...

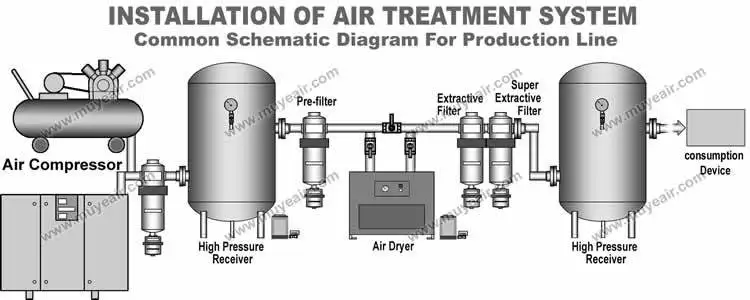

One technique would be changing the supply inlet from the bottom to the top of the compressor, to help reduce the moisture. Another would be using an aftercooler, they can remove above 50% of the liquid in an air compressor piping diagram. It must be noted, that it is impossible to keep any air compressor system free of moisture. Below are a few reasons why you shouldn't store your air dryer on your compressor and installation suggestions to help extend the life of your dryer. • Vibration: Even the healthiest and most robust air compressors will not be free of vibrations. By placing the air dryer on top of the compressor, the dryer will be absorbing those vibrations. Apr 21, 2021 · Compressed Air System Configuration. Every company’s needs are unique, but when installing a compressor system, we generally recommend that systems include a wet receiver between the compressor and air dryer and a dry receiver after the dryer. The compressor should have a moisture separator. The dryer should have a pre-filter and an after filter. The AD-IS ® air dryer and reservoir system is designed to receive compressed air from the vehicle air compressor, clean and dry the air, deliver air to the vehicle's primary reservoir, secondary reservoir and accessories, and control the compressor/dryer charge cycle. AIR DRYER AND RESERVOIR SYSTEM OPERATION: GENERAL

desiccant air dryers can provide the correct air quality, without the need for drying the complete compressed air installation, which can be both costly and totally unnecessary. Sources of contamination found in a compressed air system Contaminants in a compressed air system can generally be attributed to the following:

1. A dry, well-ventilated area is the best location for installation of the dryer. It also should be in an area where the ambient temperature will not exceed 40°C or fall below 2°C. 2. A dryer should be kept at a distance from the air compressor in order to prevent

How to Install a Refrigeration Air Dryer. This is a guide of how to install a refrigeration air dryer complete with its filters. To have a common manifold feeding into two pre-filters with two air dryers is not considered good practice. This will lead to thermal overload of one of the air dryers. For Example, the filters with the least pressure ...

QR25 series compressors should be operated in temperatures under 104°F. Principles of Dryers & Filters Moisture occurs naturally in air lines as a result of compression. Moisture vapor in ambient air is concentrated when pressurized and condenses when cooled in downstream air piping. Compressed air dryers reduce the moisture

Reduce the moisture within your air compressor piping diagrams by changing the supply inlet. This helps because water is heavier than air and drops to the bottom of the tank. Taking air from the top of a compressor means that the amount of moisture taken with it too is reduced. We also recommend that you have an aftercooler fitted with your ...

The incoming air must be free from smoke or flammable vapours which could lead to explosion or fire risks. 2.3 INSTALLATION 1. Connect the dryer to the compressed air lines indicated in the diagrams below. If not already Before attempting any installation operation, make sure that No part of system is under pressure.

Add a Dryer/Separator. For added protection against moisture and other fluids, be sure your air compressor setup is linked to an air dryer and oil/water separator. The two devices can be linked with a short airline between the outlet of the dryer and inlet of the separator. ... Air compressor installation is a useful undertaking for the avid ...

† The air dryer mounting method must be rigid enough to avoid vibration which could damage the desiccant or dryer. † The air dryer must not incline in any direction more than 15° from vertical position. † The air dryer must have at least 0.5 in (12.5 mm) free space above the cartridge canister to allow for removal during service.

C. The air dryer has been installed in a system that has been previously used without an air dryer. This type of system will be saturated with moisture and several weeks of operation may be required to dry it out. D. Location of the air dryer is too close to the air compressor. Refer to Locating AD-9 ® Air Dryer On

4. Plug in and turn on your compressor and you're ready to work without the Air Dryer. Using the Air Dryer without the bypass valve. 1. Before plugging in the compressor or the Air Dryer, open both of the shut-off valves. 2. Close the bypass valve. 3. Plug in and turn on the Compressor and Air Dryer. Shut-off Shut-off Electrical Installation ...

Home / User Manuals Stationary Compressor Manual PISTON MANUAL - REV022621.1 Piston Pump Manuals 5HP INLINE PUMP MANUAL REV030921 7.5-10HP V4 PUMP MANUAL REV030921 Freight Train Manual FREIGHT TRAIN MANUAL REV081321 Smart Air Compressor Manual Smart Air REV032921 Rotary Screw Air Compressor Manuals Eaton Compressor Rotary Screw Manual LogikaControl PLC - Logik 25-S LogikaControl PLC […]

At the vent of the air dryer, the regenerating air must flow out for approx. 10 seconds. Schematic for Testing and. Installation. Schematic 1: Schematic 2. Manual 35, Meritor WABCO System Saver TWIN Air Dryer. To obtain .. Check the entire air system for leaks, and repair as necessary.

Remove wet air by installing a refrigerated or desiccant dryer from Compressor World. Compressed air dryers are used to eliminate water moisture from your air compressor lines. Whether you're looking for an industrial or medical grade compressed air dryer, we offer a wide selection of air dyer systems and parts. Shop today for the best prices and free shipping from the experts at Compressor World!

Big sandy recc paintsville ky 606 789 4095. This is simple to read and easy to use. Eimed60jmb dryer pdf manual download. I have a new sanborn 80 gal 240volt single phase 52 hp air compressor. Make sure you use this to check voltages before connecting. View and download electrolux eimed60jmb wiring diagram online.

high-performance dryers remove the moisture from your compressed air with a standard pressure dew point of -20°C/-5°F, -40°C/-40°F and -70°C/-100°F. For complete peace of mind, you can even set your dew point to meet the specific needs of your application. Enjoy easy installation and long maintenance intervals

.jpg)

0 Response to "41 air compressor dryer installation diagram"

Post a Comment