39 ttt diagram 1018 steel

5. Please answer the following questions using the TTT diagrams and phase diagrams of alloys: Steel 4340, 1018 (A36), Al 2024 and 70-30 (260) brass a. Predict what phases will form from the following heat treatments Assume linear cooling rates: i. 4340 and 1018 (A36) cooled from 900C to below 500 C in 1 sec and room temp in less than 5 secs ii. I don't have the CCT / TTT diagrams either but, I can tell you how I do it. I quench into oil. I warm the oil up before I use it, about as warm as a HOT bath. It is important with this steel to give it a fair soak once it gets to temperature, 5 to 10 minutes if I recall correctly.

Time-temperature isothermal transformation (TTT) diagram for AISI type 6150 carbon steel, austenitized at 850°C. Continuous cooling transformation (CCT) diagrams Measure the extent of transformation as a function of time for a continuously decreasing temperature. In other words a sample is austenitised and then cooled at a predetermined rate ...

Ttt diagram 1018 steel

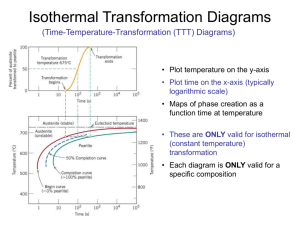

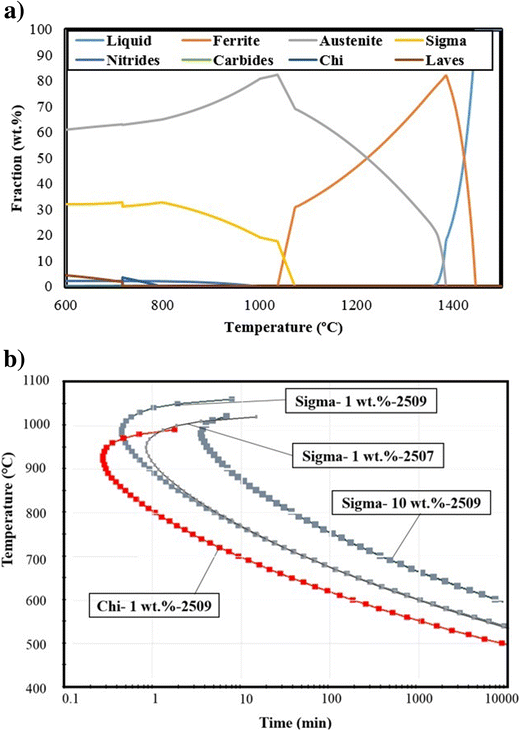

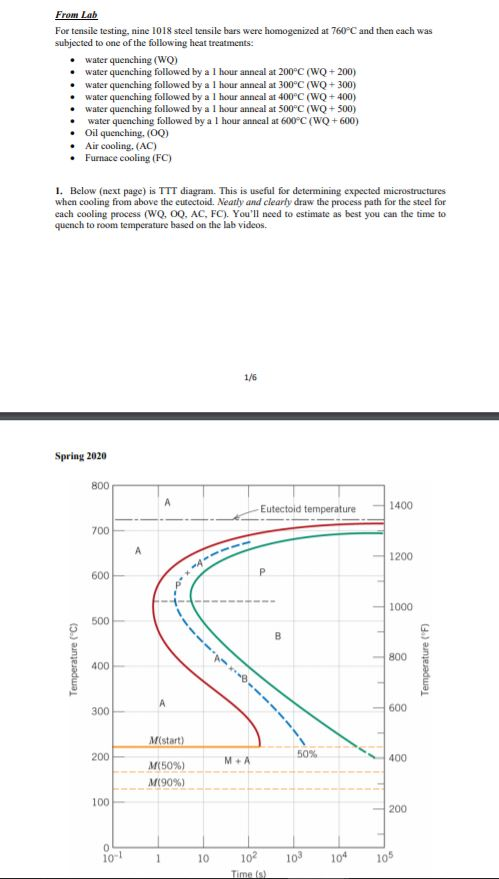

5.2 Hardness Measurements of AISI 1018 Steel (condition A) . . . 107 ... 1.2 CCT diagram for AISI 4130 steel containing 0.30% C, 0.64%. Figure 3.a shows a typical TTT diagram for plain carbon steel. The addition of carbon and alloying elements effect several parameters in TTT diagrams, such as the shape, martensite start temperature and relative position of the curve. In Figure 3.b, the effect of a small amount of Cr is seen. The TTT curve is shifted to right. Ideal TTT-curve for 0,65% carbon steel depicting time interval required for beginning, 50% and 100% transformation of austenite at a constant temperature A= Austenite F= Ferrite P = Pearlite B = Bainite. The logarithmic scale of time is used to condense results into a small space. Ae1 and Ae3 lines represent the equilibrium transformation ...

Ttt diagram 1018 steel. AISI-SAE 1018 - 0.18 % C ... be different than a TTT diagram. 15 Slow Cooling Time in region indicates amount of microconstituent! 16 Medium Cooling Cooling Rate, R, is Change in Temp / Time °C/s. 17 Fast Cooling This steel is very hardenable… 100% Martensite in ~ 1 the bridge, the steel must have sufficient strength to withstand substantial applied loads. In fact, the designer will generally select a steel with higher strength than actually required. ... 1018 Hot rolled 400 58 220 32 25 50 116 Cold drawn 440 64 370 54 15 40 126 1019 Hot rolled 405 59 225 32.5 25 50 116 ... Please answer the following questions using the TTT diagrams and phase diagrams of alloys: Steel 4340, 1018, Al 2024 and 70-30 brass a. Predict what phases will form from the following heat treatments: i. 4340 and 1018 cooled from 900C to below 500 C in 1 sec and room temp in less than 5 secs ii. 4340 and 1018 cooled from 900C to below 500 C in ... Iron carbon phase diagrams, CCT & TTT diagrams for 1018 , 1045 & 1095 Iron carbon phase diagrams, CCT & TTT diagrams for 1018 , 1045 & 1095. By oakwoodforge, February 2, 2007 in Heat Treating, general discussion. Share More sharing options... Followers 0. Reply to this topic; Start new topic ...

TTT diagram for eutectoid steel shown in relation to the Fe-Fe 3.Dec 13, · RE: Bainitic Steel, AISI metengr (Materials) 21 Sep 04 As a follow-up, I reviewed the CCT/TTT diagram for an AISI Type carbon steel and it would appear that the ferrite/austenite upper nose protrudes before the bainite nose, meaning you would form ferrite before the ... TTT diagram of hypoeutectoid and hypereutectoid steels Determination of TTT diagram for eutectoid steel Davenport and Bain were the first to develop the TTT diagram of eutectoid steel. They determined pearlite and bainite portions whereas Cohen later modified and included M S and M F temperatures for martensite. There are number of methods used to determine TTT diagrams. These are salt bath (Figs. 1- The TTT diagram for the cutectoid steel at 0.77 wt% C in the figure below shows the relation to Fe-FeC. Determine the time for: 10 Pts. 1% transformation to ...

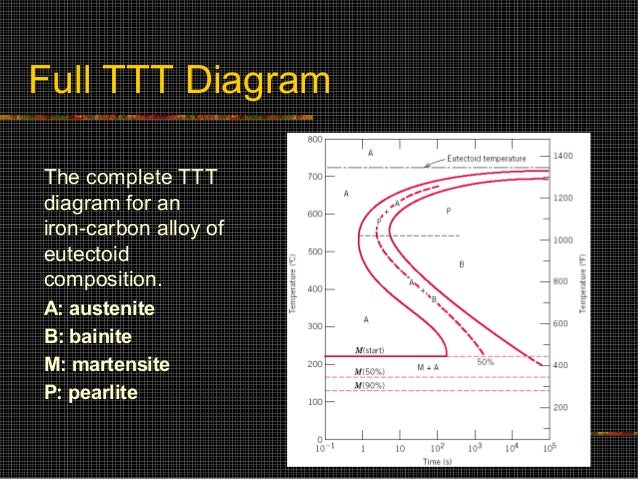

To take one example, the effect of increasing molybdenum, Figure 1. shows the TTT diagrams for a 0.4 %C 0.2% Mo steel and steel with 0.3 %C 2 % Mo, Figure 2. The 0.2% Mo steel begins to transform in about one second at 550°C, but on increasing the molybdenum to 2% the whole C-curve is raised and the reaction substantially slowed so that the ... Full TTT Diagram. The complete TTT diagram for an iron-carbon alloy of eutectoid composition. A: austenite. B: bainite. M: martensite. P: pearlite ...24 pages AISI 4130 Steel Steel name: AISI 4130 Diagram No.: 4970 Type of diagram: TTT and CCT Mat. No (Wr.Nr) designation: 1.7218 DIN designation: 25CrMo4 AISI/SAE designation: AISI 4130 Chemical composition in weight %: 0.30% C, 0.64% Mn, 1.0% Cr, 0.24% Mo Steel group: Structural steels This led to maps of isothermal transformations using a time-temperature-transformation (TTT) diagram (3, 4) for each steel composition. These diagrams have been developed for many compositions using several approaches (5). Isothermally-transformed specimens are highly useful in teaching interpretation of microstructures.

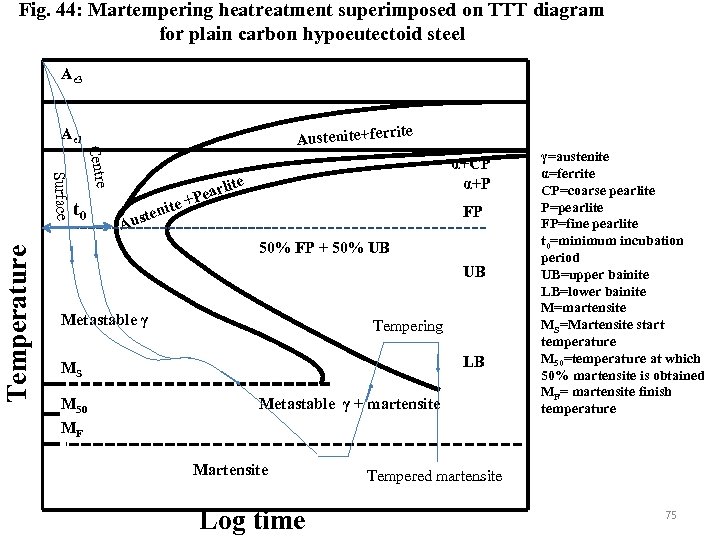

As shown in complete TTT diagram for eutectoid steel in figure above approximately 550°C-600°C, austenite transforms completely to pearlite. Below this range up to 450°C, both pearlite and bainite are formed. Finally, between 450°C and 210°C, the reaction product is bainite only.

TTT diagram indicates when a specific transformation starts and ends and it also shows what percentage of transformation of austenite at a particular temperature is achieved. Look at figure 1b and 1c. Figure 2. Upper half of TTT Diagram(Austenite-Pearlite Transformation Area) Figure 2 represents the upper half of the TTT diagram.

BTW When you hear those quench times from the TTT diagrams, it's not refering to the time between the oven and the oil (although that's a major factor). It's refering (in broad, general terms) to the speed of getting from the lowest austenite temp to the upper martensite temp. In other words from about 1500 degrees to 400 degrees.

The effect of alloying on the shape of the TTT diagram is shown in Figure 8. Figure 7: Comparison of the effect of carbon on the TTT curves of plain carbon steel. Left is SAE 1020 steel. Right is SAE 1080 steel. Carbon pushes the nose (or knee) of the TTT curve to the right, retarding kinetics [3].

Mar 3, 2008 — Equalibrium Phase diagrams, for 1018 and 4340 steels, Brass, and Al 2024 are given in the book. e. TTT diagrams or hardness vs. time: For steel ...27 pages

1040 Steel Steel name: 1040 Steel Diagram No.: 2638 Type of diagram: CCT SAE designation: 1040 Chemical composition in weight %: 0.39% C, 0.72% Mn, 0.23% Si, 0.010% P, 0.018% S Steel group: Structural steels Note: Grain size: 7-8. Reference: Not shown in this demo version. Transformation Diagram Price: 30.00 US $ Buy Online Transformation Diagram

On the next page is the TTT diagram for 1019 steel, which also works for 1018 steel. This is useful for determining expected microstructures when cooling from above the eutectoid. Neatly and clearly draw the continuous-cooling path for the steel for each cooling process (WQ, OQ, AC, FC).

May 4th, 2019 - 5 Please answer the following questions using the TTT diagrams and phase diagrams of alloys Steel 4340 1018 A36 Al 2024 and 70 30 260 brass ...

by R Manna · Cited by 9 — TTT diagram stands for “time-temperature-transformation” diagram. It is ... Determination of TTT diagram for eutectoid steel.108 pages

Read the effect of alloying elements on TTT curve in any physical metallurgy book or ASM handbook. This will provide you an insight on the transformation curve and products. I have not failed. I've just found 10,000 ways that won't work." — Thomas Edison. RE: Compare the TTT diagram of 1018 and 4340.

Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels.This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain's curve.The effect of time-temperature on the microstructure changes of steel can be shown by the TTT diagram.

TTT diagram for a hypereutectoid Steel (1.13 wt% C) 54. ©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning ™ is a trademark used herein under license. Figure 12.8 The TTT diagrams for (a) a 1050 and (b) a 10110 steel. 55. Contineous Cooling Transformation (CCT) Diagram ...

Getting Real: The TTT Diagram. Here is the "official" isothermal TTT diagram for eutectoid carbon steel. It is not all that different from the unofficial TTT diagram for the pure iron above, except that the γ → α transformation temperature is now at 723 oC (1333 o F). Look up the phase diagram if you wonder about this.

Dec 15, 2018 — CCT diagrams allow predictions of hardness and microstructure in ... As can be seen in the diagrams, the AISI 5160 steel has a greater ...

Here we show a variety of different steel microstructure outcomes depending on different TTT diagram heat treatments.

The TTT diagram of steel is considered an important transformation diagram for non-equilibrium transformation.There are various non-equilibrium products like Martensite, Bainite which can not be formed by continuous cooling and so can not be explained with phase transformation diagram explained in Martensitic transformation post and Widmanstatten transformation post.

Transformation-temperature-time (TTT) curves can be used to illustrate the effect of alloying elements on retarding diffusion-assisted transformations. Figure 1 shows the effect of nickel on TTT curves by comparing nickel-free UNS G41400 (SAE/AISI 4140) steel vs. UNS G43400 (SAE/AISI 4340), a nickel-containing LAS of similar composition, Table 1.

Fig. 3.5 The TTT diagram calculated using the Kirkaldy model[7] and the Li model[13] fo r the AISI 4140 steel and ASTM Grain Size number of 7.5 reported for the published TTT diagram^261 shown in Fig. 3.4. Subscript Notation: FL S: Start line for ferrite by the Li Model[13], FK S: Start line for ferrite by the Kirkaldy Model[7] PL

Ideal TTT-curve for 0,65% carbon steel depicting time interval required for beginning, 50% and 100% transformation of austenite at a constant temperature A= Austenite F= Ferrite P = Pearlite B = Bainite. The logarithmic scale of time is used to condense results into a small space. Ae1 and Ae3 lines represent the equilibrium transformation ...

Figure 3.a shows a typical TTT diagram for plain carbon steel. The addition of carbon and alloying elements effect several parameters in TTT diagrams, such as the shape, martensite start temperature and relative position of the curve. In Figure 3.b, the effect of a small amount of Cr is seen. The TTT curve is shifted to right.

5.2 Hardness Measurements of AISI 1018 Steel (condition A) . . . 107 ... 1.2 CCT diagram for AISI 4130 steel containing 0.30% C, 0.64%.

0 Response to "39 ttt diagram 1018 steel"

Post a Comment